Aug 2001

Malaysia's newest power project, the Manjung Power Plant, is located on the West coast of Peninsular Malaysia, 260 km north of Kuala Lumpur in Perak. It will also be the largest coal fuelled power station in the country. TNBJ, the national power utility, awarded a turnkey design and construct contract to a joint venture between Alstom and Peremba with the civil engineering works being carried out by Leighton Contractors Malaysia.

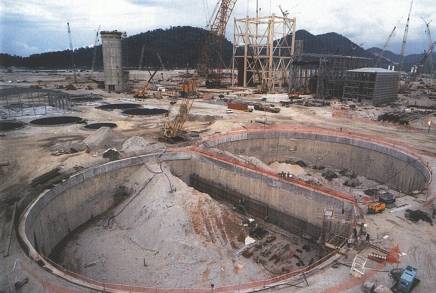

The power plant

project is being built on a 'Power Island' just off the

coast to allay environmental concerns. The recently

reclaimed island is to be the site of the 3 x 700 MW

plant. One of the most time critical structures of the

project was the pump house and associated water pond.

However, its design was complicated by the geology of the

site. Although not far from the mainland, the reclaimed

sand platform sits on soft marine clays overlying recent

alluvial deposits, making it complex to excavate the 20 m

deep sea water intake and pumping station in future. The

initial design envisaged a sheet pile cofferdam. However,

from a practical point of view the numerous strut levels

would have made excavation and construction costly and

very time consuming. Specialist geotechnical contractor

Bachy Soletanche Malaysia developed an alternative scheme

for the construction of the pump house which was adopted

by the engineer in the ultimate design.

Figure of eight shaft -61 & 59m diameter

with depths 30-40m

The solution consisted of using a diaphragm wall

retaining wall to form the water pool and the pump house

without any need for internal strutting. This was done by

creating a figure of eight shape, with one section for

the water pool and the other slightly larger section for

the pump house proper. The figure of eight shaft

consisted of two touching circles which are 61 m and 59 m

in diameter with panel depths of 30 to 40 m deep. The use

of the diaphragm wall to contribute load bearing capacity

meant that only 31 barrettes foundations, 60 m deep, were

required to found the heavy pump house structure and

equipment. This also contributed to the savings in time

as initially eighty large diameter bored piles had been

anticipated. The diaphragm wall and foundation work was

completed in about 12 weeks between June to August 2000.

This allowed the rapid excavation of the water pool and

pump house and the construction and installation of the

critical mechanical equipment.

However, while the design is very efficient, the

construction of any circular shaft needs to be carried

out in accordance with strict tolerances to ensure the

highest quality of work. Due to the nature of the

circular retaining structures, their efficiency derives

from the hoop action of the compressive forces. This

means that the accuracy of the diaphragm wall panel

joints must be controlled to ensure that the compressive

forces are transmitted between the two structural

elements. Any deviation between the panels reduces the

surface area available and therefore the capacity of the

hoop structure to resist the forces. To ensure compliance

with the strict 1:200 tolerances, Bachy Soletanche

Malaysia used the highly accurate KS3000 hydraulic grab

to excavate the diaphragm wall panels and barrettes.

Incorporated in the grab is an inclinometer that gives

real time readout in the operator's cab showing the

verticality in both planes. Any deviation outside can

immediately be corrected. The KS3000 equipment is used

regularly in Malaysia, Indonesia and Singapore but

normally for its high productivity rate. This was one of

the first instances it was used in Asia for such

tolerance critical work. The compressive forces discussed

above come together for both shafts at the two

intersection points — another quality critical

point.

Apart from the delicate excavation of these two Y shaped

panels, the reinforcement cage detail was very important.

For ease of construction and installation, the 'cage'

consisted of four elements, a triangular central cage and

three normal reinforcement cages for each leg'. All four

elements had to be overlapping which made for complex

manoeuvring of cranes on site." To enable the

accurate placing of all this reinforcement, the

triangular or 'spider' cage was placed in the

intersection of the Y with its legs' extending to each

side of the panel. Next the three normal reinforcement

cages were lowered into each leg of the Y, interlocking

with the triangular cage, which acted as a guide. Once

all the cages were safely and accurately installed in the

panel, universal beams were then placed in the pump house

and water pool sides of the Y panel to further reinforce

this 'pinch' point. Concreting was undertaken using three

tremie pipes which were filled together to ensure the

highest quality finish. In addition to these two special

panels, there were a number of other special panels for

the water intake tunnels and the pipe work leading to the

power station from the pump. To ensure structural

integrity around the future openings, specially designed

reinforcement panels were installed into the wall. This

innovative design and construction method is the first

such application in Southern Asia, according to Bachy

Soletanche. Similar but smaller projects of this nature

have been carried out by Bachy Soletanche in Hong Kong

and Korea.

The advantages to the programme and structure were

significant. With the retaining structures being

incorporated into the permanent works, further cost

savings were obtained. Such structures are often used in

Europe for storm water retention as the highly efficient

design and the rapid construction time ensures minimum

disruption to the surrounding properties. The equipment

used incorporates sophisticated electronic and hydraulic

systems, is reliable, and adapted to the works of this

nature. It is a reliable alternative to the Hydrofraise

diaphragm wall cutter for accuracy.

Extract from Southeast Asia Construction.